Material enters the sluice box from the trommel and tailings are reprocessed 2 times

Material enters the sluice box from the trommel and tailings are reprocessed 2 times

Conveyor for moving raw material to the hopper and trommel.

Conveyor for moving raw material to the hopper and trommel.

Currently, this batch sampling system can process up to 60 tons per day.

View of the hopper and trommel before material enters into the sluice box.

View of the hopper and trommel before material enters into the sluice box.

Secure building for the shaking table, centrifugal concentrator, and the smelting furnace.

Secure building for the shaking table, centrifugal concentrator, and the smelting furnace.

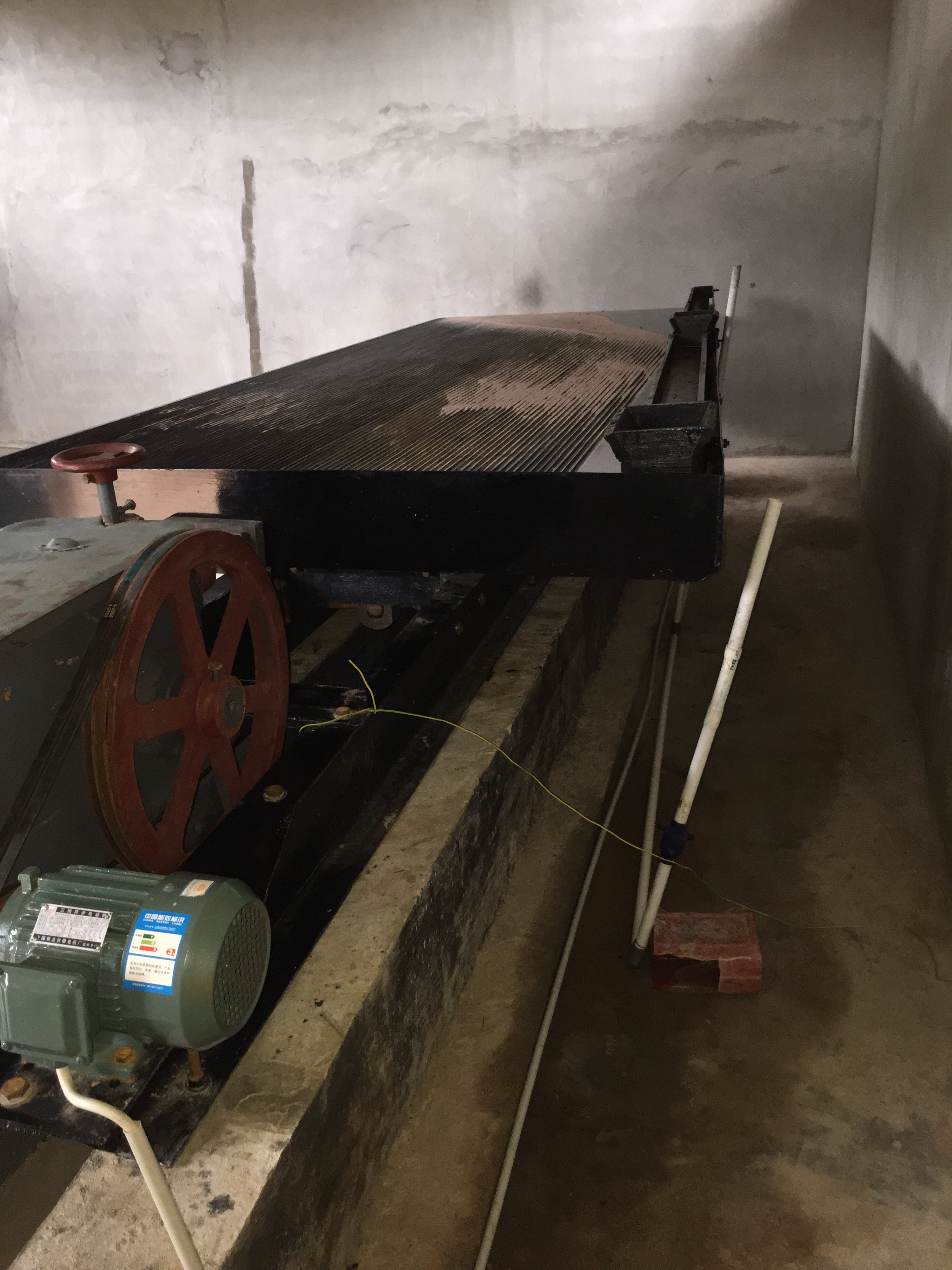

Shaking table used to separate the fine gold from other elements.

Table is set upon concrete base and can be adjusted by independent leveling system.